|

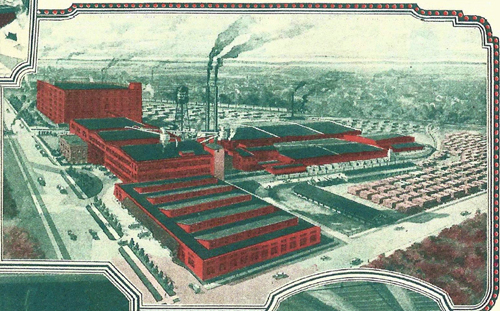

By the mid 19th century and the onset of the industrial revolution, production of architectural woodwork was taking place on a large scale in factories. Most of today's woodworking machines were in use long before the advent of electricity, and were powered by pulleys, steam or water.

The vast forest lands of the Great Lakes and the Pacific Northwest provided the raw materials for lumber and millwork used for homebuilding. Catalogs, such as The Universal Millwork and Sears and Roebuck, standardized styles and part numbers for millwork companies. The vast forest lands of the Great Lakes and the Pacific Northwest provided the raw materials for lumber and millwork used for homebuilding. Catalogs, such as The Universal Millwork and Sears and Roebuck, standardized styles and part numbers for millwork companies.

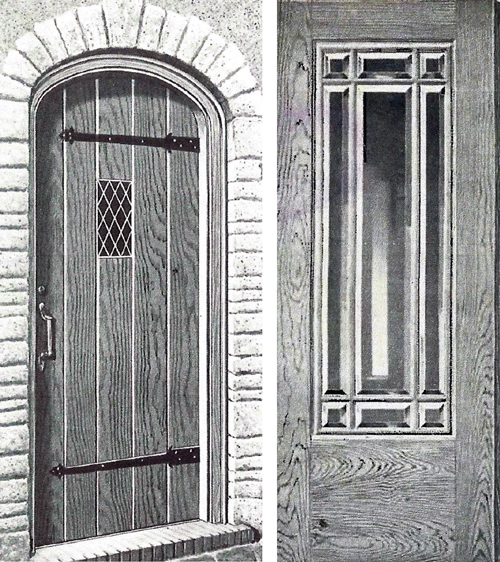

Traditionally doors were built with solid wood stiles (vertical pieces) and rails (horizontal pieces) and assembled with mortise and tenon joinery. Today many modern doors are built in the same design but are lacking the traditional joints that make a door last for 100 years.

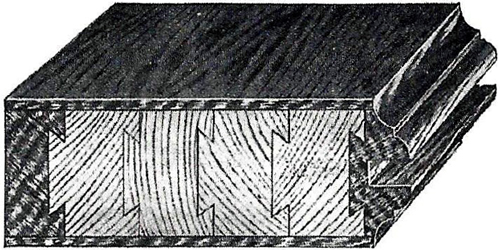

Around 1900, production of doors changed so that many doors were veneered. A veneered door has an interior core made of an array of small blocks glued together or layers of thin boards glued in alternating directions. This seems to have been an effective way to use a large amount of scraps and lower grade wood. This solid core was then covered on both faces with thick veneers. The interior of these doors usually matches the interior wood trim used in the formal areas of the house. The exterior veneer could be different and is quite often quarter sawn white oak. Many of these doors would have windows cut out or arch tops. Traditional rail and stile doors were also being produced in this manor.

In 1915 a typical front door would cost $10 but could run as much as $12.50 with beveled/leaded art glass. With proper maintenance many of these doors are still in use in our older neighborhoods. This design is still in use today although the cores are particleboard, strandboard, foam, or gypsum board. |

|